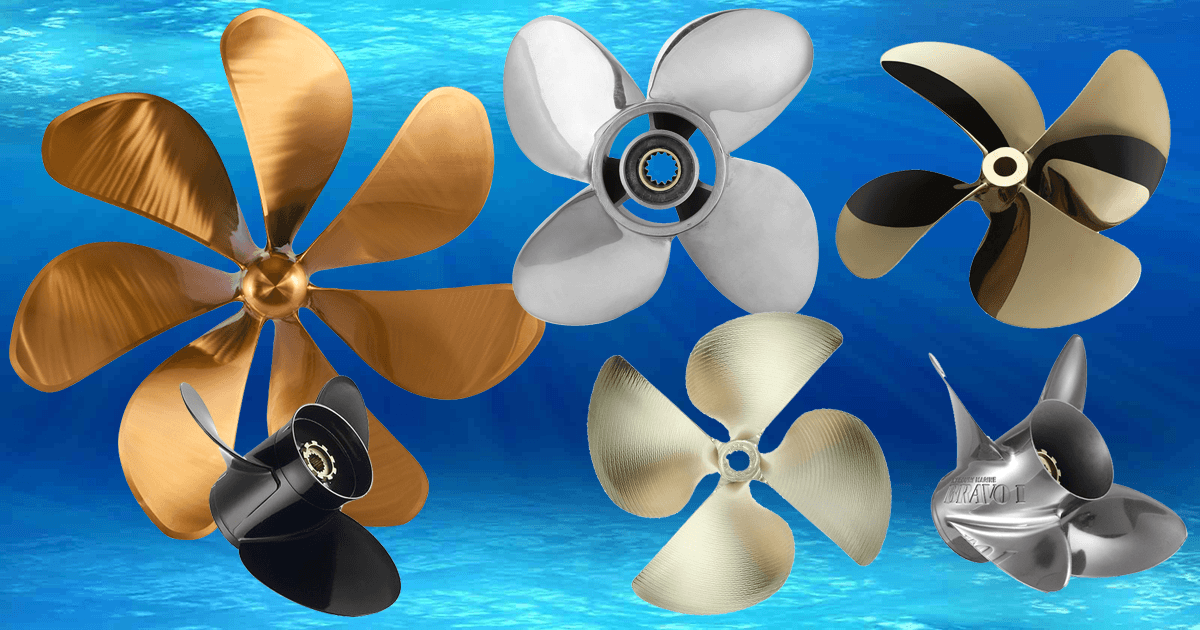

Navigating through the vast waters, marine vessels rely heavily on the efficiency and durability of their propellers. These crucial components are not just about shape and size; the material they are made from plays a pivotal role in their performance and longevity. Let's delve into the differences between boat propellers crafted from various materials and understand why these differences matter.

Aluminum propellers indeed strike a balance between affordability and functionality for recreational boating. Their lightweight nature not only contributes to better fuel efficiency but also allows for easier handling and less strain on the engine, particularly beneficial for smaller vessels. While they may not match the durability of stainless steel propellers, with proper maintenance, aluminum propellers can still offer a long service life. It's important for boaters to regularly inspect their propellers for any signs of damage, such as dents or corrosion, and to follow the manufacturer's guidelines for care and replacement. This proactive approach can help extend the lifespan of aluminum propellers and ensure safe and enjoyable boating experiences.

Stainless steel propellers indeed embody a superior choice for marine applications, reflecting a harmonious blend of durability and performance. Their robust construction not only resists corrosion but also thrives under the demanding conditions of the sea. This resilience is particularly beneficial for commercial vessels that traverse vast and varied waters, as well as for high-performance boats that demand uncompromised thrust. The weight of stainless steel, while greater than other materials, contributes to a steadier and more powerful propulsion.

Furthermore, the longevity of these propellers means that they retain their shape and functionality over time, reducing the need for frequent replacements or repairs. In the event of damage, the material's malleability allows for effective restoration, ensuring that the propellers can be returned to their pristine state, thus safeguarding the investment made in high-quality equipment.

Brass propellers are the reliable choice for various boating conditions. They are particularly valued for their performance in both freshwater and saltwater environments. However, brass propellers are susceptible to dezincification, especially in polluted or saltwater, which can weaken the metal over time. Despite this, the advantages of brass, including its affordability and the higher copper content that compensates for the zinc, generally outweigh the disadvantages.

One of the advantages of cooper propellers is their construction, often made from durable materials that withstand harsh marine environments. They are designed to provide efficient thrust and maneuverability, which is essential for various boating activities. However, one must consider the type of vessel and usage when selecting a propeller, as the wrong choice can lead to reduced performance or damage to the propulsion system. For instance, propellers with more blades may offer better control at low speeds but could potentially reduce top-end speed.

Manganese bronze alloys serve as a middle ground between aluminum and stainless steel. While not as strong as Nibral or stainless steel, manganese bronze propellers offer better durability than aluminum and are less expensive than Nibral. They are a viable option for boat owners who seek a balance between performance and cost without venturing into the higher-priced territory of stainless steel or Nibral.

Nickel-Bronze-Aluminum, commonly known as Nibral, is a hardy alloy that offers superior strength and corrosion resistance. This material is often used in commercial boat propellers where durability is paramount. Nibral's hardness allows for precise shaping, which can lead to improved efficiency and performance. Although it comes at a higher cost, its longevity and the reduced need for repairs can make it a cost-effective choice in the long run for vessels that demand the utmost reliability.

The choice of propeller material is a critical decision that should align with the vessel's purpose, the conditions it will face, and the owner's budget. Aluminum propellers suit leisurely outings and lighter boats, while stainless steel is ideal for high-performance and commercial use. For those in between, manganese bronze offers a compromise, and for the toughest conditions, Nibral stands as the robust contender.

In the end, understanding the unique properties of each material helps in selecting the right propeller that propels a boat forward and ensures a journey that is efficient, safe, and in line with the mariner's needs. Whether it's the lightweight agility of aluminum, the sturdy resilience of stainless steel, the hardened performance of Nibral, or the economical balance of manganese bronze, each material brings its own set of advantages to the helm. Choose wisely, and sail smoothly.

For those ready to make an informed decision on their marine propeller needs, PropTech Propellers is here to guide you through the process. With a wide range of high-quality propellers and a team of skilled technicians, we ensure that your vessel is equipped with the best fit for its mission. Whether you're looking to purchase a new propeller or require expert repair services, PropTech is your go-to source for all things propellers. Contact us today to learn more about our products and services and let us help you navigate the waters with confidence and efficiency. Sail ahead with PropTech, where performance and precision meet.

Calling our office connects you directly with experts who can offer precise information and clear pricing.